Systems that fit exactly

Whether in the articulation segment, on the side of the vehicle, in the roof or even outside the vehicle: HÜBNER power connection systems can be integrated into the bus gangway in many different ways. The layout of the cabling and other characteristics of the system are always adjusted to the requirements of the vehicle and the wishes of the customer. All HÜBNER power connection systems have one thing in common: They are optimally protected against damage and they're designed to handle any and all vehicle movements – for the long term and with minimal wear and tear.

Routing cables and hoses from the front vehicle segment to the back segment is a particular challenge with articulated buses. Cables and hosing need to move as the vehicle moves but must not under any circumstances kink or break. To achieve the best possible functionality and durability, power connection systems from HÜBNER are specifically configured for each customer and integrated into the structure of the vehicle. The focus is on tested quality: On request, each connection packet can be examined on a test rig before being put into operation.

Perfect coordination

Whether it has to do with the number and dimensions of the lines or their stiffness and configuration – all characteristics are customized to fit the needs of the customer and to coordinate perfectly with one another. This ensures that cable systems keep up with all the movements of the bus, and that wear and tear in the flexible lines is kept to a minimum.

Power connections in the articulation segment

With the Universal Articulation and the Compact Articulation, the hose and cable lines can be conducted comfortably through the area of the articulation system without affecting the floor height of the vehicle. Lines with a diameter of up to 30 mm can be routed directly through the articulation itself.

Power connections in the side sections

The power connection system in the side sections is suitable for both low-floor and high-floor buses. Cables, lines and coils are laid out so that they stay optimally positioned during each bend that the bus makes.

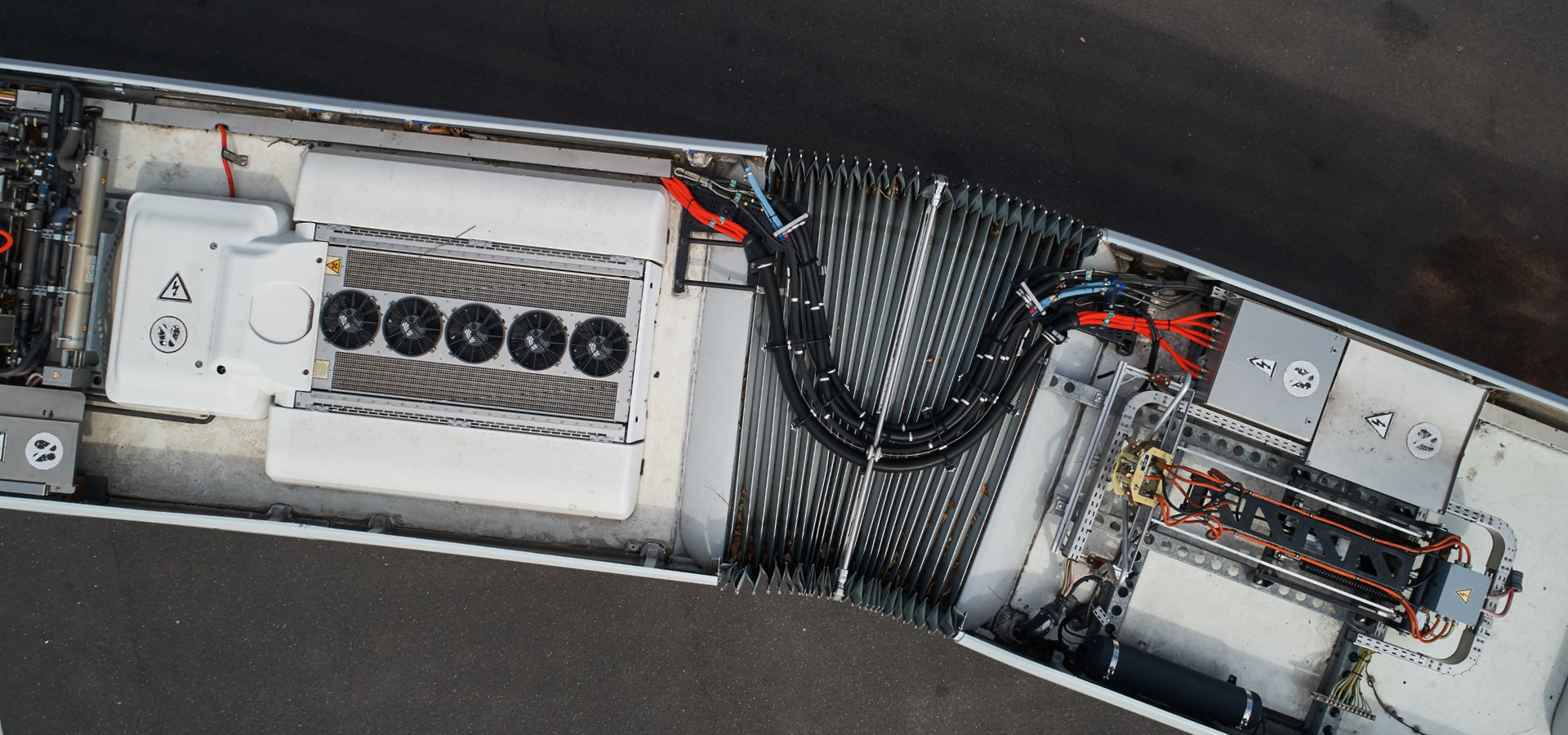

Power connections in the roof area

For this, HÜBNER uses the proven power connection system in C-form. This type of cable routing ensures low-wear movements, avoiding extreme kinking of the lines. The optional bulkhead plates that can be mounted on the front and rear vehicle segments facilitate the installation of cable packets in the vehicle and create a clear interface.

Power connections in the bus exterior – Our new S-EGS

For the e-mobility challenge, HÜBNER has developed its own power connection system for electric, hybrid and trolley buses. With the innovative new system, high-voltage lines, battery lines, potential compensation cables and lines for conducting liquids can be laid on the exterior of the vehicle. The benefit: The relative movement of the lines to one another is minimized in this way, and wear resulting from exterior environmental factors is essentially eliminated. The lines can also be very well protected against UV and weather impacts.

Currently power connection packets with a total weight of up to 70 kg can be realized – with cables having an exterior diameter of up to 42 mm. There are various individual options for the optical design of the cable routing. For example, cables can be covered laterally or through a complete folding bellows attachment and thus incorporated in the overall vehicle design.